Britain has a long and rich history when it comes to making the world’s finest furniture. One company that is continuing this incredible legacy is the British firm Silverlining whose innovative creations are highly sought after all over the world.

Silverlining’s creations adorn some of the most amazing places and objects throughout the world. The company prides itself on being at the forefront of design, craft and technology and the materials they use are quite simply mind-boggling.

They won’t think twice when provided with the opportunity to use 3000 years old Bog Oak or join an expedition to salvage a 235-year-old reindeer hide from the Metta Catharina, which for the history-buffs among you, sank in 1786 off the Plymouth coast.

Their research and innovation department is constantly pushing technological advancements with the sole goal of creating something beautiful and quite extraordinary.

“We’re more than a modern furniture-maker; we’re a progressive design company. When you think about Silverlining Furniture and the quality of its pieces, think about the highest automotive standards. All materials and finishes we work with go through a rigorous testing process to meet our global clientele’ needs.

The pieces that leave the workshop don’t only have to look spectacular, but they have to perform. In the same way that a Patek Phillipe Watch or a Bugatti motor car would.” says Daniel Lloyd-Davies, research and development manager at Silverlining Furniture.

Climate simulations

Accelerated Weather Chambers are machines used at the Silverlining workshop to simulate weather conditions from around the world. They create special environments that speed up the weathering process – 1000 hours in the chamber is equal to 1 year of weathering.

The Xenon Arc test simulates the weathering process of indoor and outdoor conditions, with altering temperature, humidity and sunlight, whilst the QUV test – simulates the damaging effects of UV light.

“Florida is a great example of a destination for which our furniture pieces have to be tested in both machines, as the climate there varies a lot. We would use the Xenon Arc test to simulate the heat of the day, the drop in temperature at night, both humid and dry days, wet stormy weather and direct sunlight. With all these factors controlled, we can see how our pieces will fair in this environment,” says Luke Briggs, Head of Production.

Fingerprint-proof furniture

“Our clients are often very private, yet very high profile. In response to their needs for increased security, we have been tirelessly working on a fingerprint-resistant lacquer. We have made some significant headway in recent months and hope that with further development, we will be able to start applying the lacquer to any required furniture piece in the near future,” says Lloyd-Davies.

Innovation Friday

Innovation Friday is a Silverlining initiative that brings all employees together for one Friday in a month to pursue and share their passion projects.

Mark Boddington, Silverlining Furniture founder, says: “Innovation is at the heart of what we do. We have seen countless examples from the Silicon Valley of new products and services being developed due to employees having the freedom to explore their interests.

That’s why we have launched Innovation Friday, to allow our team to be creative, brave and playful, creating a new perspective when it comes to materials, techniques and finishes.”

Cosmic Compass is one of the most successful designs which came out from Innovation Friday. It features multiple radiating etched lines that create a sunburst pattern which has subsequently been added to several pieces. Innovation Friday has also inspired a design that repurposes what would be considered as ‘waste’.

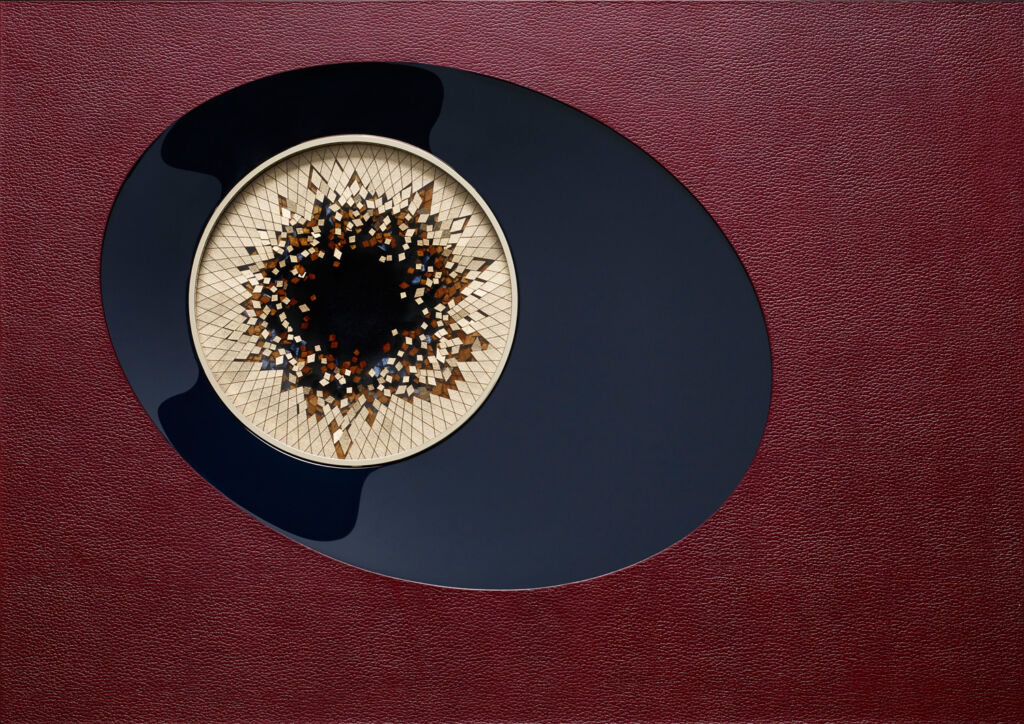

The ‘Big Bang’ design (pictured above) uses rhomboid-shaped fragments of quilted differentially blue-dyed quilted maple, rippled sycamore and myrtle wood veneer and moon-gold-leaf shards, which appear to float in a clear ‘window’ of casting resin.

This design came from an investigation into how to create decorative finishes from small offcuts of wood veneer and other leftover materials. The ‘Big Bang’ design can now find the ‘Big Bang’ design on some of the newer Silverlining projects.

New materials

The R&D team is also involved with UK universities on material research and innovation, focusing on reusing waste materials and working with sustainable materials. As a result, the company now offers a palm-wood ‘leather’ finish (pictured below).

It is produced by treating palm leaves – a by-product of the coconut industry – with glycerine and water to make them soft and pliable. In addition to this, the team is currently working on developing a viable alternative to plastic from rattan woods.

![]()

You must be logged in to post a comment.