Building a respected company with only 100 clients almost defies belief. Some might say it’s impossible. However, Silverlining, the bespoke British furniture company, has been able to do this. What makes their story so remarkable is their success has not been founded upon 100 clients; they’ve been able to build their enviable reputation with less than 80!

British company Silverlining is known for making exceptional furniture using rare and precious materials. At its helm is Mark Boddington, a scion of the famous brewing family. Mark, along with a 70-strong team of designers, are incredibly passionate about making bespoke furniture that can best be described as extraordinary. In this feature, we look into what it is that Silverlining has been doing over the past three decades that keep it expanding with what will be considered by almost every other business, a relatively small number of clients.

“In over 35 years of Silverlining Furniture, we have worked with less than 80 clients,” says Mark Boddington, the company founder. “Yet it hasn’t hindered our business in any way. On the contrary, it has accelerated it throughout continuously working with our early clients – and now their children – on new commissions, testing the limits of what’s possible when it comes to both the time-honoured techniques and the technological advancements in furniture making,” he adds.

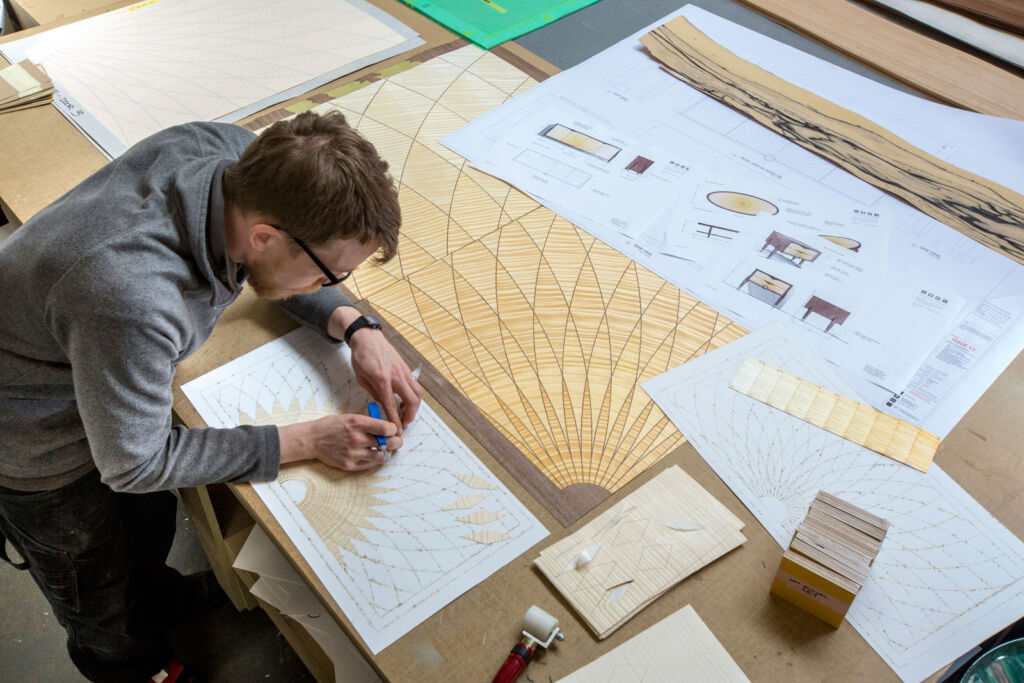

What attracts clients to Silverlining at first is its team’s insatiable desire to show what is possible by innovating and experimenting with new techniques and finishes, often bringing together traditional methods with the latest technologies. What keeps the clients working with Silverlining is how involved they are in the whole process.

Jason Chadda, Silverlining’s director and the key point of contact for its international client base, says, “Our clients travel from all over the world to visit our workshop and HQ in Wrexham, Wales. Although it’s an unassuming building from the outside, once you step in, you’re transported into the world of what we call ‘Making Magic’. The world of precision, skill, imagination, technique, craft, technology and art.

Our clients not only witness our processes but also try their favourite techniques themselves. We bring our clients as close as possible to our materials, techniques and our craftspeople so that together we’re fully committed to the shaping of the future of furniture-making.”

The design brief often emerges from conversations with the clients through an ideas exchange. “Our clients are innovators, aesthetes and intellectuals. They work with the finest architects, artists, yacht, and jet designers. They’re in the know when it comes to the latest technologies and innovations.

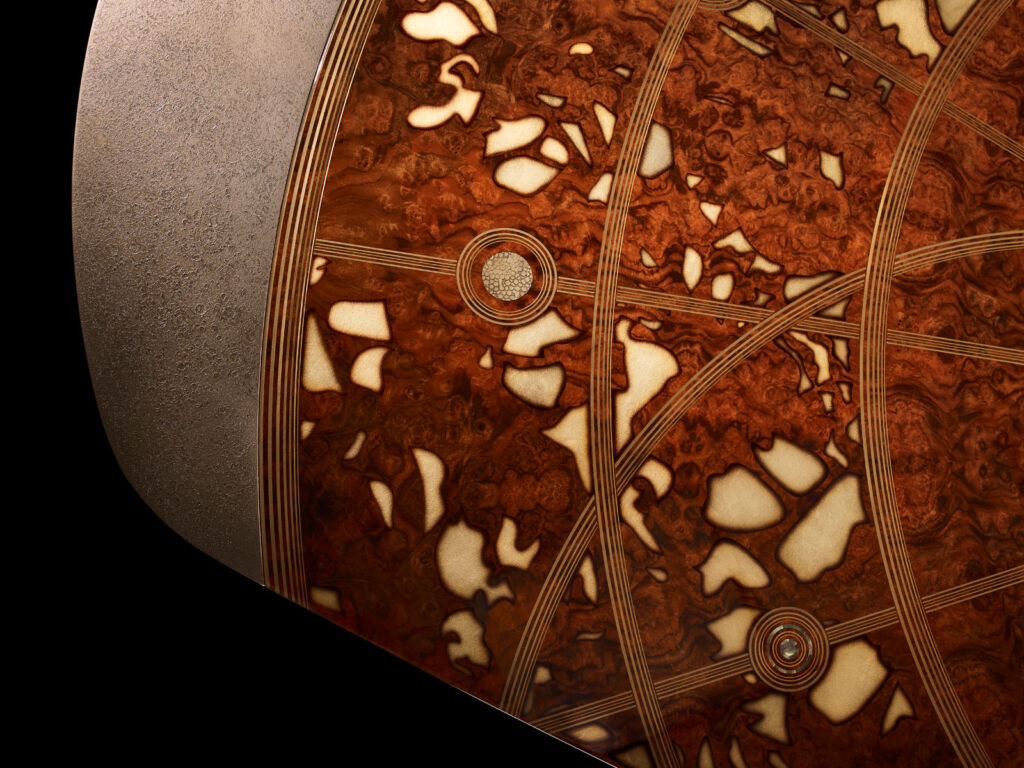

It’s their lifestyles and inspirations that we translate into pieces of furniture. And for our clients, these are so much more than functional objects. The Silverlining pieces are of a strong personal significance and are treated as works of art – one-off pieces that can’t be found anywhere else in the world,” says Jim Birch, Silverlining’s head of design.

Commissions are very often personal to the client – a recent dining table was not only a table for banquets with a rotating turntable, but it also housed a pop-up drinks cabinet with the client’s collection of rare drinks.

Other commissions include a coffee table decorated with the imprints of the plane tree leaves collected from the grounds of the client’s family home, an artwork of the constellation arrangement above them on the night their child was born, and a hunting lodge table inspired by the Spanish moss that grows on the large oak trees that line the entrance to the property.

The research and development team are also crucial in the commissioning process. “The pieces that leave the workshop don’t only have to look spectacular, but they have to perform – just in the same way a Patek Phillipe Watch or a Bugatti motor car would,” says Daniel Lloyd-Davies, research and development manager at Silverlining Furniture.

“All materials and finishes we work with go through a rigorous testing process to meet the needs of our global clientele. Their needs are our driving force – whether we’re testing adverse weather conditions or experimenting with fingerprint-proof finishes,” he adds.

Each Silverlining piece that leaves the workshop takes thousands of hours to make, a great collaborative feat between the client and the company’s designers, engineers, craftspeople, and project managers.

“Furniture-making at Silverlining is a true Renaissance discipline – it’s the coming together of bright, ambitious minds, and the most skilled hands, to create extraordinary pieces,” says Boddington. Adding, “That’s what makes our clients come back for more – they know that together we can make the seemingly impossible happen”.

Read more design news and features here.

![]()

You must be logged in to post a comment.